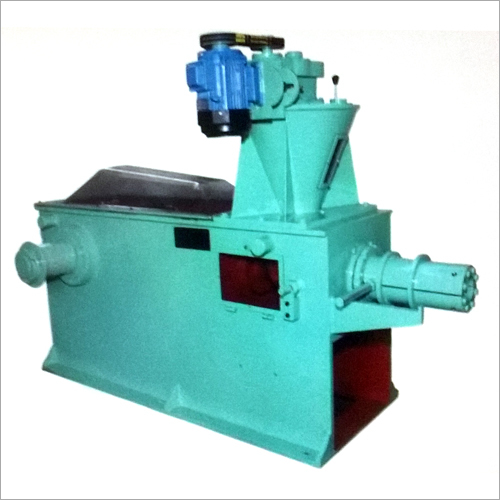

Briquetting Press Machine

Briquetting Press Machine Specification

- Product Type

- Briquetting Press Machine

- General Use

- Biomass Briquetting, Agro Waste, Industrial Applications

- Material

- Steel / Alloy Steel

- Product Shape

- Cylindrical Briquette

- Type

- Other

- Computerized

- No

- Roller Material

- Forged Manganese Steel

- Briquette Size

- 60 mm diameter (customizable)

- Feature

- Energy Efficient, Rugged Structure, High Output

- Color

- Green & Grey

- Installation

- Foundation Mounted

- Lubrication System

- Centralized Automatic

- After Sales Service

- Onsite Installation & Training

- Operating Temperature Range

- 5C to 45C

- MoistureOfMaterial

- 8-15%

- Briquetting Pressure

- 15-20 MPa

- MaterialLength

- 5 mm

- Maintenance

- Low Maintenance Required

- Noise Level

- Below 70 dB

- Application Area

- Biofuel Manufacturing, Metal Powder Compacting, Recycling

- SolidDensity

- 1.2 - 1.4 t/m

- Safety Feature

- Overload Protection, Emergency Stop Switch

- Control Panel

- Digital Control Panel Included

- Feeding System

- Automatic Screw Feeder

About Briquetting Press Machine

We are emerging as one of the fastest growing companies engaged in manufacturing and supplying Briquetting Press Machine. This machine converts diverse residues like forestry, industrial and agriculture waste into solid blocks of bio-fuel. It can handle most kinds of biomass materials, such as bark, cardboard, cellulose, cotton stalk, hay, paper, wood chips and wood dust. We manufacture this machine under the firm guidance of expert supervisors using high quality mild steel and cast iron. Briquetting Press Machine makes cylindrical shaped briquettes using binder less technology with high mechanical pressure.

Features:

- Less power consumption

- Easy installation

- High working efficiency

Advanced Control and Automation: Equipped with a digital control panel and PLC system, operation of the briquetting press is both intuitive and precise. Automatic screw feeding and centralized lubrication improve efficiency and reduce manual intervention. Operators benefit from user-friendly interfaces, ensuring consistent product quality and simplified troubleshooting

Reliable Safety and Durability: With a rugged steel or alloy steel build, the machine incorporates overload protection and emergency stop switches for optimal workplace safety. Designed for foundation mounting, it remains stable even at high outputs. Centralized lubrication and efficient cooling systems extend service life while minimizing wear.

Versatile Applications and High Efficiency: Ideal for biofuel manufacturing, recycling, and industrial uses, the press handles materials with 815% moisture and up to 5 mm length. Producing customizable cylindrical briquettes, its 7.515 kW motor ensures high-density output (1.21.4 t/m) with minimal noise below 70 dB, making it suitable for varied operational environments.

FAQs of Briquetting Press Machine:

Q: How does the automatic feeding system work in the Briquetting Press Machine?

A: The machine features an automatic screw feeder that consistently supplies material into the pressing chamber, ensuring uniform feeding and stable briquette formation without frequent manual intervention.Q: What safety features are integrated into the control panel and machine operation?

A: Safety measures include overload protection to prevent damage during excessive load and an emergency stop switch that allows instant shutdown, promoting a secure operating environment for users.Q: When should maintenance be performed on the briquetting machine?

A: With low-maintenance requirements, routine inspections mainly involve checking lubricant levels and ensuring the centralized automatic lubrication system is functioning properly. Manufacturers recommend periodic scheduled maintenance according to operational intensity.Q: Where can this briquetting press be installed and used?

A: Designed for foundation-mounted installation, the machine is suitable for use in biofuel manufacturing plants, metal recycling centers, and agro-industrial sites. Onsite installation and training services are available across India.Q: What types of materials can be processed, and what are the requirements?

A: The press efficiently compacts biomass, agro waste, and powdered metals with moisture content between 8% and 15% and a maximum material length of 5 mm, ensuring optimal briquette density and strength.Q: How does the machine benefit production processes in industrial settings?

A: With high output (up to 1500 kg/hr), energy efficiency, and robust construction, the machine enhances productivity, reduces waste, and can be adapted for Automatic or Semi-Automatic operation depending on workflow requirements.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Biomass Briquette Press Machine Category

Biomass Briquetting Press Machine

Minimum Order Quantity : 1 Piece

Material : Other, Steel

Computerized : No

Color : Other, Green and Yellow

Product Type : Biomass Briquetting Press Machine

General Use : Briquetting biomass waste for fuel

Biomass Briquette Press Machine

Minimum Order Quantity : 10 Pieces

Material : Other, Briquette

Computerized : No

Color : Blue

Product Type : Biomass Briquette Press Machine

General Use : Industrial

Hammer Mill Grinder Briquetting Machine

Material : Other, Mild Steel, Alloy Steel (rollers)

Computerized : No

Color : Other, Green & Grey

Product Type : Hammer Mill Grinder Briquetting Machine

General Use : Briquetting biomass, sawdust, agrowaste, and other residues

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS