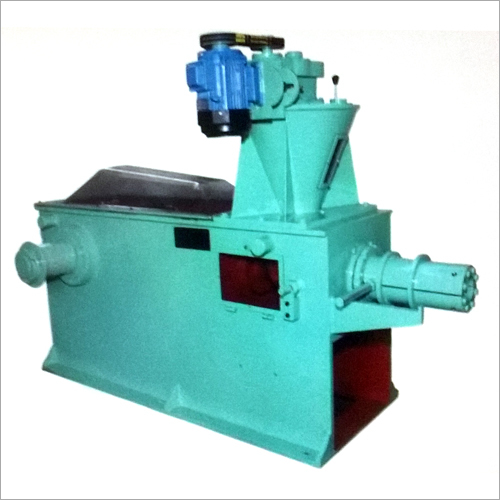

Biomass Briquetting Press Machine

Price 250000 INR/ Piece

Biomass Briquetting Press Machine Specification

- Product Type

- Biomass Briquetting Press Machine

- General Use

- Briquetting biomass waste for fuel

- Material

- Steel

- Product Shape

- Cylindrical Briquettes

- Type

- Other

- Computerized

- No

- PLC Control

- No

- Roller Material

- Alloy Steel

- Briquette Size

- 70 mm diameter

- Feature

- High output, energy saving, robust construction

- Color

- Green and Yellow

Biomass Briquetting Press Machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Main Domestic Market

- All India

About Biomass Briquetting Press Machine

Biomass Briquetting Press Machine is made from finest grade components. This automated Biomass Briquetting Press Machine is extensively used for industrial and commercial applications. This press machine has high tensile strength and consumes less power. The advanced mechanical structure of the press machine helps in providing dust free environment. This press machine has higher durability in using all kinds of industrial and agricultural raw materials. This wear-resistant press machine is easy to operate and offers optimum stability for longer time.

BIOMASS BRIQUETTING PRESS MACHINE TYPE:-

- BP 50150

- BP 60175

- BP 65200

- BP 75200

- BP 90200

- BT 90200

FOR RAW MATERIAL:-

- RICE HUSK

- SAW DUST

- COFFEE HUSK

- MUSTURD HUSK

- CANE TRASH

- JUTE WASTE

INDUSTRIALAND AGRICULTURAL WASTE: A Biomass Briquetting Press Machineconverts various waste materials, such as agricultural and forestry residues, into high-density, cylindrical "bio-coal" briquettes for use as a renewable energy source.The process involves compressing the dry, powdery raw material under high pressure and heat, which releases lignin that acts as a natural, binderless glue.The resulting briquettes are a cost-effective, non-polluting fuel that can replace fossil fuels, making the process an eco-friendly way to manage waste and create a sustainable energy solution.

How it works

- Feed Preparation: Dry biomass waste, such as sawdust, straw, rice husks, and other agricultural or forestry residues, is collected and fed into the machine.

- Pre-compression: A screw conveyor or other mechanism pre-compresses the material and forces it into a feeder box.

- Briquette Formation: A high-pressure system, either mechanical (like a ram or piston) or hydraulic, forces the material through a die (a mold).

- Binderless Technology: The high pressure and generated heat soften the lignin present in the biomass, acting as a natural binder and eliminating the need for chemical binders.

- Finishing: The formed, dense, cylindrical briquettes exit the die and may pass through a natural cooling system before being discharged.

Key features

- Waste-to-Energy:Converts agricultural and forestry waste into a valuable energy fuel.

- Environmentally Friendly:Produces a non-polluting fuel (bio-coal) that helps preserve natural resources and reduce global warming.

- Binderless Process:Utilizes the natural binding properties of lignin, making the briquettes free of chemical binders.

- Durable and Stable:Designed for heavy-duty continuous operation with wear-resistant components and high structural strength.

- Versatile:Can process a wide range of raw materials, including wood waste, agricultural residues, and paper waste.

- Cost-Effective:Offers a profitable and cost-effective solution for fuel production.

Engineered for Efficiency and Durability: Built from high-grade steel with alloy steel rollers, this mechanical press boasts a rugged, welded structure. Its robust design and automatic lubrication pump ensure reliable, low-maintenance operation, even under continuous use. An oil cooling system for the main shaft further increases equipment longevity and upholds consistent output quality.

User-Friendly and Safe Operation: This semi-automatic press features an easy-to-use screw conveyor feeding system and chain drive, delivering a quiet working environment below 80 dB. Safety is paramount, with built-in emergency stop and overload protection mechanisms. The clear, straightforward interface means no need for computerized or PLC controls, making it accessible for operators of varying skill levels.

Versatile Application and High Productivity: Suitable for processing a wide range of biomass wasteincluding sawdust, rice husk, and other agricultural residuesthe machine produces ready-to-use, cylindrical briquettes with a 70 mm diameter. With a peak output of 1500 kg/hr, it is ideal for industrial-scale fuel production and energy saving in various settings across India.

FAQs of Biomass Briquetting Press Machine:

Q: How does the Biomass Briquetting Press Machine process waste materials into fuel briquettes?

A: This machine uses mechanical compression, driven by a chain drive system and screw conveyor, to press sawdust, rice husk, or other agricultural waste into cylindrical briquettes. The waste is compacted at high pressure without external binders, resulting in dense, ready-to-use solid fuel briquettes.Q: What safety features are included in the machine, and how do they protect operators?

A: Safety is ensured with an emergency stop button, allowing operators to halt operation immediately in urgent situations. Overload protection prevents damage to components and reduces injury risk by stopping the machine if excessive pressure is detected.Q: When should routine maintenance be performed, and what is the expected service life?

A: Routine maintenance, such as checking the lubrication system and inspecting the rollers, should be performed as recommended by the manufacturer (usually monthly or after set production hours). The machines automatic lubrication pump and durable alloy steel construction support a service life of 810 years under normal use.Q: Where can this briquetting press be installed for optimal results?

A: It is suitable for installation in industrial plants, biomass processing units, or biofuel manufacturing facilities with adequate space (minimum 3200 x 900 x 1700 mm) and a 380V power supply. The robust structure and oil cooling system enable reliable operation in varying Indian climates (from -10C to 45C).Q: What types of raw materials are compatible with this machine?

A: The press is designed to handle a variety of biomass waste, primarily sawdust, rice husk, and other dry agricultural residues. These materials should be properly dried and sized for the best compression and briquette quality.Q: How energy efficient is the briquetting press compared to other machines?

A: With a power consumption below 45 kW per hour and main motor rated at 37 kW, the machine offers high production output (up to 1500 kg/hr) while minimizing energy usage. This makes it a cost-effective and environmentally friendly solution for biomass waste processing.Q: What are the benefits of using this briquetting press for businesses and end-users?

A: Businesses benefit from transforming low-value waste into high-density, marketable fuel briquettes, optimizing energy costs, and reducing waste handling. End-users receive uniform, high-quality solid fuel that is easy to transport and store, supporting sustainable energy practices.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Biomass Briquette Press Machine Category

Biomass Briquette Press Machine

Material : Other, Briquette

Product Type : Biomass Briquette Press Machine

General Use : Industrial

Color : Blue

Computerized : No

Briquetting Press Machine

Material : Other, Steel / Alloy Steel

Product Type : Briquetting Press Machine

General Use : Biomass Briquetting, Agro Waste, Industrial Applications

Color : Other, Green & Grey

Computerized : No

Briquette Size : 60 mm diameter (customizable)

Hammer Mill Grinder Briquetting Machine

Material : Other, Mild Steel, Alloy Steel (rollers)

Product Type : Hammer Mill Grinder Briquetting Machine

General Use : Briquetting biomass, sawdust, agrowaste, and other residues

Color : Other, Green & Grey

Computerized : No

Briquette Size : 60 mm (diameter) x 100 mm (length) (Approx.)

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS